Compact, Economical, Efficient: SBR Small WWTP with Integrated Pump Technology

AQUATO® PUMP

At AQUATO®, we present the PUMP: a small WWTP that combines a proven SBR process with state-of-the-art pump technology. It is specifically designed to be compact, lightweight, and exceptionally easy to maintain. The AQUATO® PUMP features low energy consumption and high performance, all while remaining highly versatile and adaptable. We guarantee outstanding treatment results that significantly exceed legal limit requirements. The system can be effortlessly installed in concrete or plastic tanks for both new builds and retrofits.

-

•

Compact & Economical Design

-

•

Simple Handling and Maintenance

-

•

High Versatility

-

•

Low Energy Consumption

-

•

Excellent Effluent Quality

-

•

Flexible Application

AQUATO® PUMP

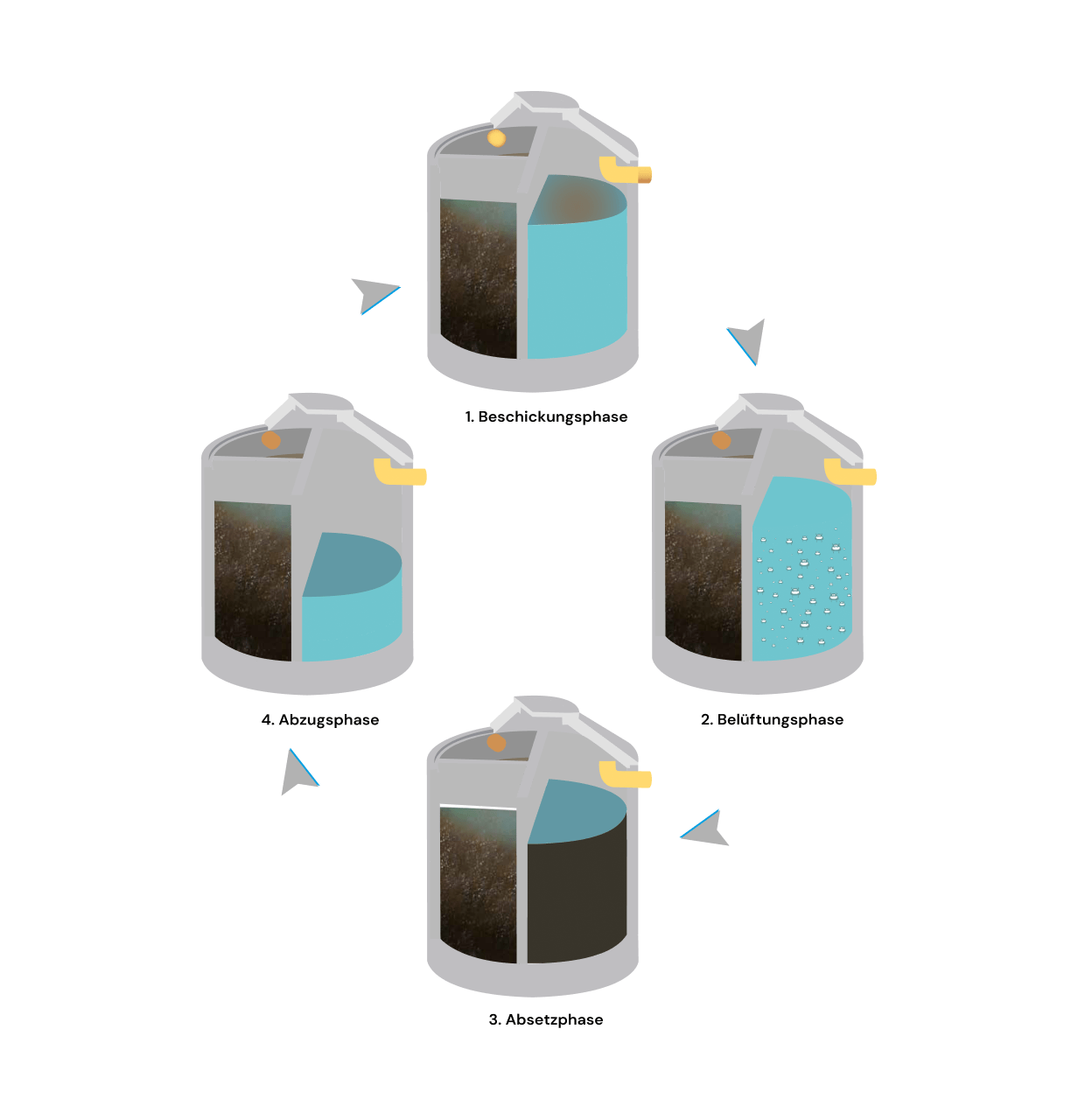

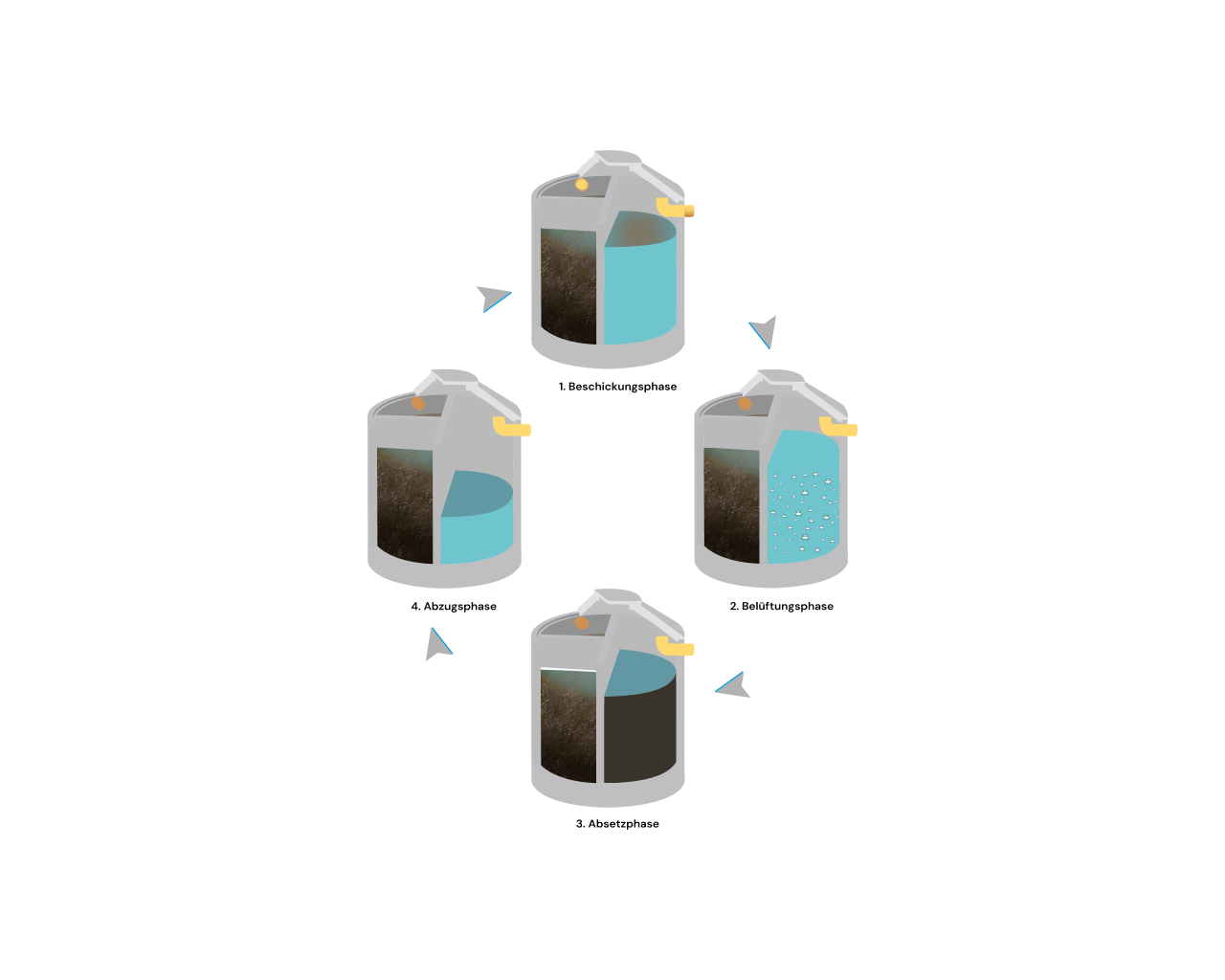

How Does the SBR Process Work?

The AQUATO® PUMP utilizes the SBR process (Sequencing Batch Reactor) for fully biological wastewater treatment. This proven process operates efficiently in modern single- or multi-chamber tanks and easily adapts to older, existing tanks.

All processes are precisely managed by the K-PILOT 2.4 control system in a regular four-phase cycle:

Only aerobically stabilized sludge is produced, significantly reducing disposal requirements. This results in considerable cost savings for you.

How Does the SBR Process Work?

The AQUATO® PUMP utilizes the SBR process (Sequencing Batch Reactor) for fully biological wastewater treatment. This proven process operates efficiently in modern single- or multi-chamber tanks and easily adapts to older, existing tanks.

All processes are precisely managed by the K-PILOT 2.4 control system in a regular four-phase cycle:

Only aerobically stabilized sludge is produced, significantly reducing disposal requirements. This results in considerable cost savings for you.

AQUATO® PUMP

Scope of Delivery

Every AQUATO® wastewater treatment system is delivered with all components necessary for smooth and reliable operation. The technology, including the control unit and submersible motor aerator, is easily accessible. A complete solution for fully biological wastewater purification.

Tanks

Sampling

Outdoor Columns & Installation Options

Smart Tools and Extensions: Digital Intelligence for Your Wastewater System

Expand the functionality of your AQUATO® wastewater treatment plant systems with our intelligent tools and modules. We provide customized solutions for advanced control, comprehensive monitoring, and optimized efficiency.

Control

Smart Extensions

K-PILOT 2.4

Newly developed control for maximum flexibility and long service life.

Wi-Fi Direct

Convenient wireless access and wireless updates.

Makes your K-PILOT 2.4 IoT-enabled for remote access and cost savings.

Control

K-PILOT 2.4

Newly developed control for maximum flexibility and long service life.

Wi-Fi Direct

Convenient wireless access and wireless updates.

Smart Extensions

Makes your K-PILOT 2.4 IoT-enabled for remote access and cost savings.

Additional Treatment Stages

H-Modul

Chemical-free UV disinfection for maximum hygiene and water reuse.

CL-Modul

Cost-effective chlorine disinfection to meet specific requirements.

P-Modul

Effective phosphorus elimination to protect sensitive water bodies.

C-Modul

Stable nitrogen removal even with fluctuating plant loads.

H-Modul

Chemical-free UV disinfection for maximum hygiene and water reuse.

CL-Modul

Cost-effective chlorine disinfection to meet specific requirements.

P-Modul

Effective phosphorus elimination to protect sensitive water bodies.

C-Modul

Stable nitrogen removal even with fluctuating plant loads.

FAQs

You have questions? We have answers!

What is Unique About the AQUATO® PUMP's Pump Technology?

The AQUATO® PUMP features modern pump technology that provides high versatility. It is height-adjustable to easily accommodate all tank variants. This ensures simple and secure installation using plug-and-play operating units.

Is the AQUATO® PUMP Energy-Efficient?

Yes, the AQUATO® PUMP is highly energy-efficient. It includes an integrated economy mode that ensures high performance while maintaining minimal power consumption. This significantly reduces operating costs.

Can the AQUATO® PUMP Be Used in All Tank Types?

Absolutely. The AQUATO® PUMP is exceptionally flexible and suitable for all approved tank types—whether concrete or plastic, round or square. It is ideal for both new builds and retrofits.

Ready to Assist.

Let our expertise guide you. Contact us for a personalized consultation and receive detailed information about our systems and available extensions.

Provide your email – we’ll contact you soon.