Fully Biological Wastewater Treatment: The Fixed-Bed Process for Stability

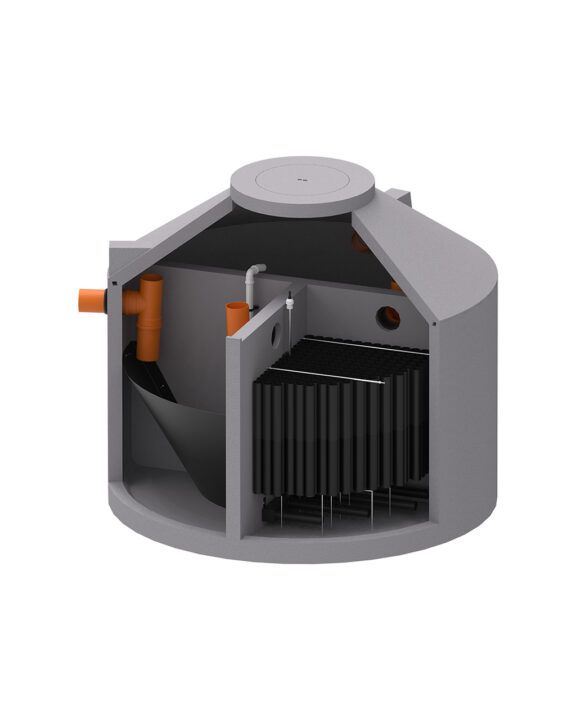

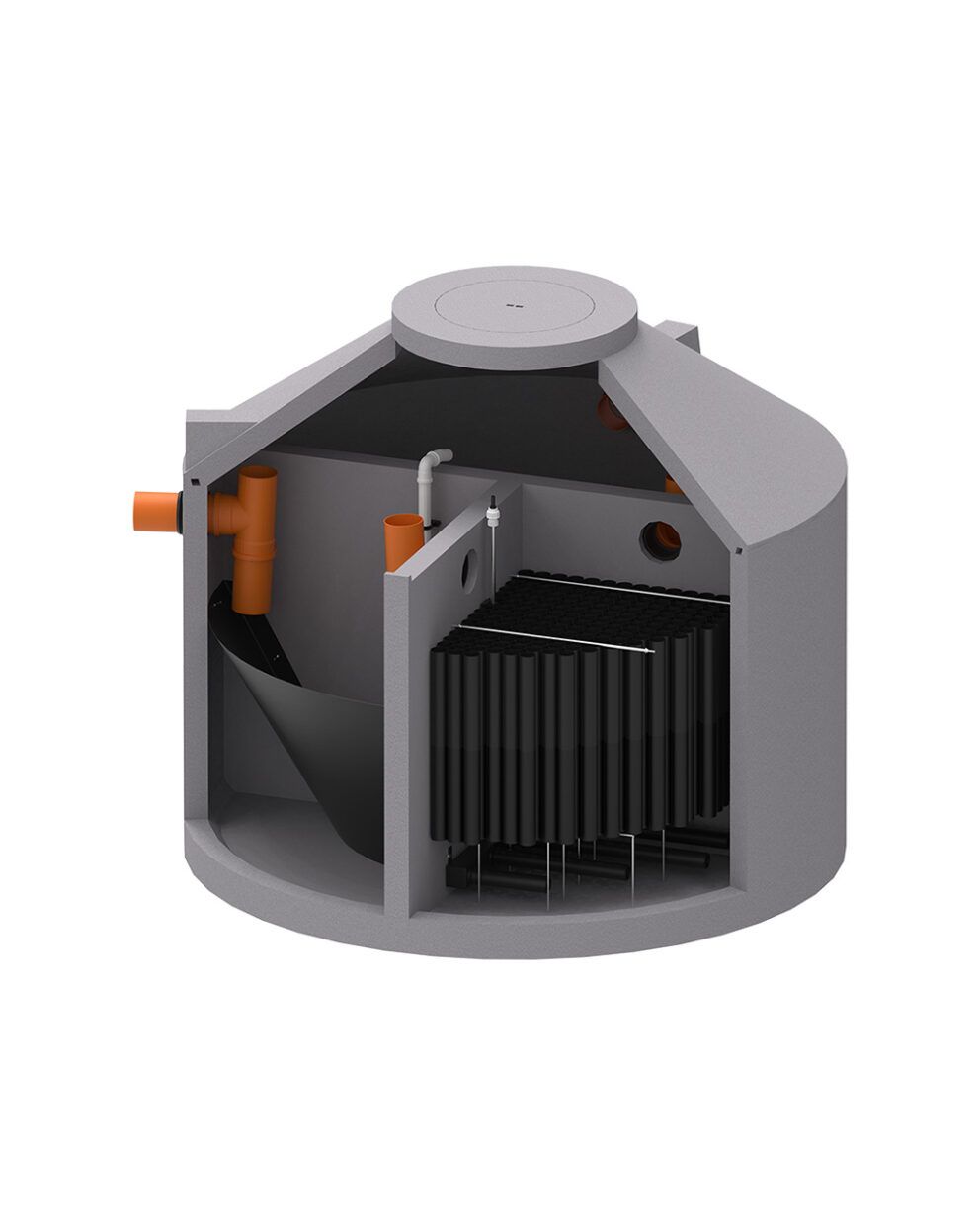

AQUATO® 3K-PLUS

At AQUATO®, we introduce the 3K-PLUS: a reliable small WWTP that ensures consistently high purification performance through the proven fixed-bed process.

It is one of our biofilm systems and offers exceptional operational stability, even under low-load conditions and at low external temperatures. The system contains no in-tank mechanical components, utilizes wear-free tank components made from recyclable materials, and ensures maximum long-term operational safety. It is ideal for new construction or retrofitting into existing three-chamber systems

-

•

Components Made from Recyclable Materials

-

•

Consistently High and Reliable Purification Performance

-

•

Reliable Operation Under Low-Load Conditions

-

•

Easy Retrofitting into Existing Systems

-

•

Optimal Purification Performance Starting at 1 Person

Variant

AQUATO® 3K-PLUS

How Does the Fixed-Bed Process Work?

The Fixed-Bed Process (FB) is a proven, continuously operating method for biological wastewater treatment. It utilizes fixed-bed media where microorganisms settle to form a stable biofilm. The wastewater is then gradually passed through several chambers for step-by-step purification.

This process is simple, robust, and low-maintenance. Since the majority of biological degradation occurs directly on the fixed-bed media, the plant ensures highly stable operation, even with fluctuating loads.

Sampling takes place during the final clarification phase.

How Does the Fixed-Bed Process Work?

The Fixed-Bed Process (FB) is a proven, continuously operating method for biological wastewater treatment. It utilizes fixed-bed media, providing a surface for microorganisms to settle and form a stable biofilm. The wastewater is then gradually purified as it passes through several chambers.

This process is simple, robust, and inherently low-maintenance. Because the majority of biological degradation occurs directly on the fixed-bed media, the system ensures highly stable operation, even under fluctuating loads.

Sampling is conducted during the final clarification phase.

AQUATO® 3K-FLOW

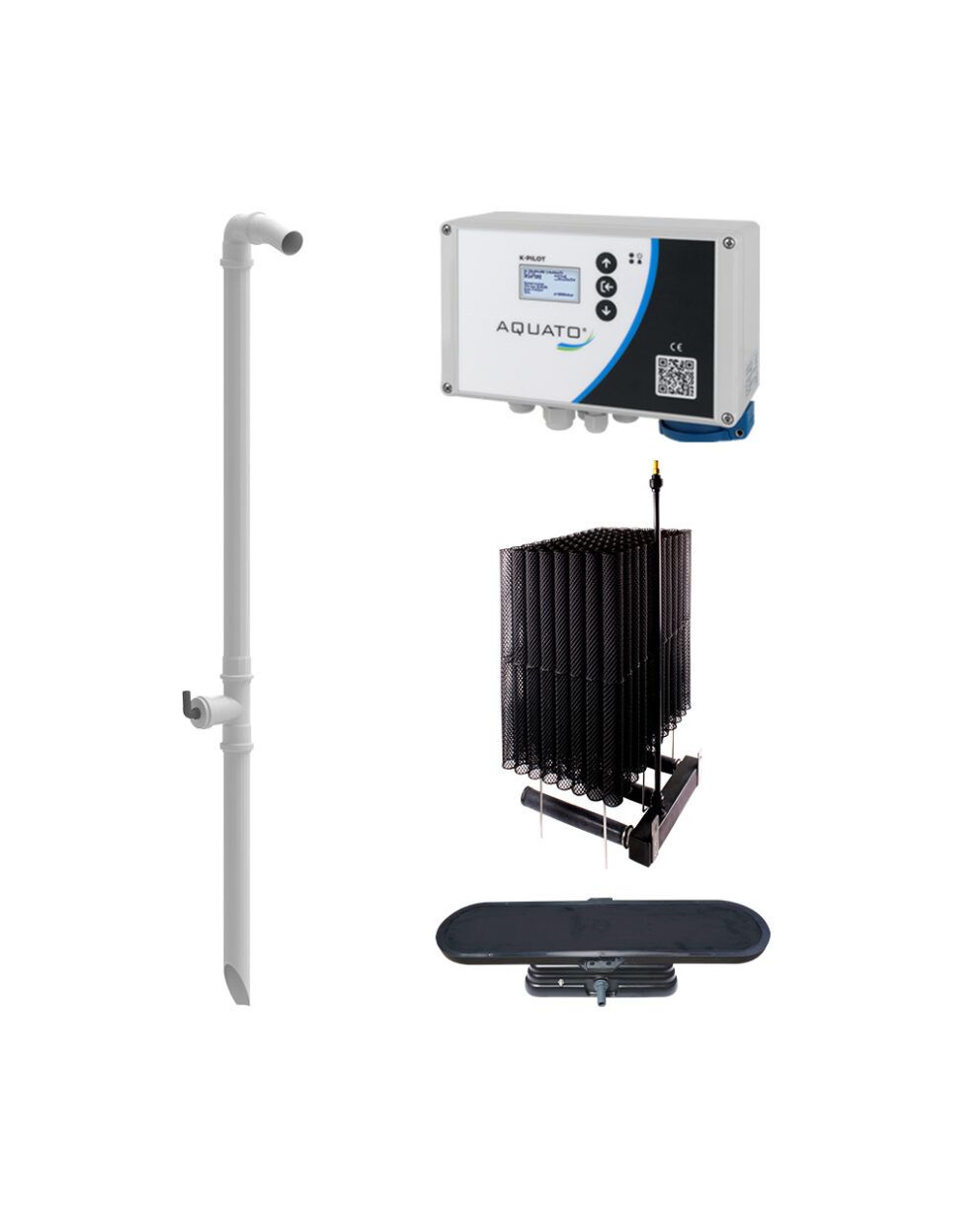

Scope of Delivery

Every AQUATO® system is delivered complete with all necessary components for smooth and reliable operation. The technology, including the control unit and compressor, is conveniently located in a dry, easily accessible area outside the tank. A comprehensive solution for fully biological wastewater purification.

Tanks

Outdoor Columns & Installation Options

Outdoor Column 6.1T

Outdoor Column X7

Smart Tools and Extensions: Digital Intelligence for Your Wastewater System

Expand the functionality of your AQUATO® wastewater treatment plant systems with our intelligent tools and modules. We provide customized solutions for advanced control, comprehensive monitoring, and optimized efficiency.

Control

Smart Extensions

K-PILOT 2.4

Newly developed control for maximum flexibility and long service life.

Wi-Fi Direct

Convenient wireless access and wireless updates.

Makes your K-PILOT 2.4 IoT-enabled for remote access and cost savings.

Control

K-PILOT 2.4

Newly developed control for maximum flexibility and long service life.

Wi-Fi Direct

Convenient wireless access and wireless updates.

Smart Extensions

Makes your K-PILOT 2.4 IoT-enabled for remote access and cost savings.

Additional Treatment Stages

H-Modul

Chemical-free UV disinfection for maximum hygiene and water reuse.

CL-Modul

Cost-effective chlorine disinfection to meet specific requirements.

P-Modul

Effective phosphorus elimination to protect sensitive water bodies.

C-Modul

Stable nitrogen removal even with fluctuating plant loads.

H-Modul

Chemical-free UV disinfection for maximum hygiene and water reuse.

CL-Modul

Cost-effective chlorine disinfection to meet specific requirements.

P-Modul

Effective phosphorus elimination to protect sensitive water bodies.

C-Modul

Stable nitrogen removal even with fluctuating plant loads.

FAQs

You have questions? We have answers!

What is special about the fixed film process of the AQUATO® 3K-PLUS?

The fixed film process utilizes tubular support media that provide an optimal habitat for cleansing microorganisms. This ensures consistently high and reliable purification performance, guaranteeing stable operation even under low-load conditions and at low external temperatures.

Are electrical components installed in the water in the AQUATO® 3K-PLUS?

No, the AQUATO® 3K-PLUS system operates without any energized or mechanically stressed components inside the tank or in the wastewater area. This maximizes operational safety and simplifies maintenance.

Can the AQUATO® 3K-PLUS be integrated into existing tanks?

Yes, the 3K-PLUS is ideally suited for retrofitting. It can be installed in existing concrete tanks. Custom adaptation to accommodate older tank sizes is also possible.

Ready to Assist.

Let our expertise guide you. Contact us for a personalized consultation and receive detailed information about our systems and available extensions.

Provide your email – we’ll contact you soon.