Wastewater Treatment Without External Power: The Soil Filter System

AQUATO® BKF

At AQUATO®, we introduce the BKF: an innovative Soil Filter System that operates entirely without external power. This system leverages natural processes for the fully biological treatment of domestic wastewater. It provides a simple, reliable solution that requires minimal maintenance and ensures groundwater protection. The AQUATO® BKF is an environmentally friendly, sustainable choice, perfect for rural areas lacking sewer connections.

-

•

Wastewater Treatment Without External Power

-

•

Natural, Fully Biological Treatment

-

•

Low Maintenance and Highly Reliable

-

•

Uniform Wastewater Distribution

-

•

Efficient Pollutant Reduction

-

•

Simple and Accessible Sampling

How does the BKF work?

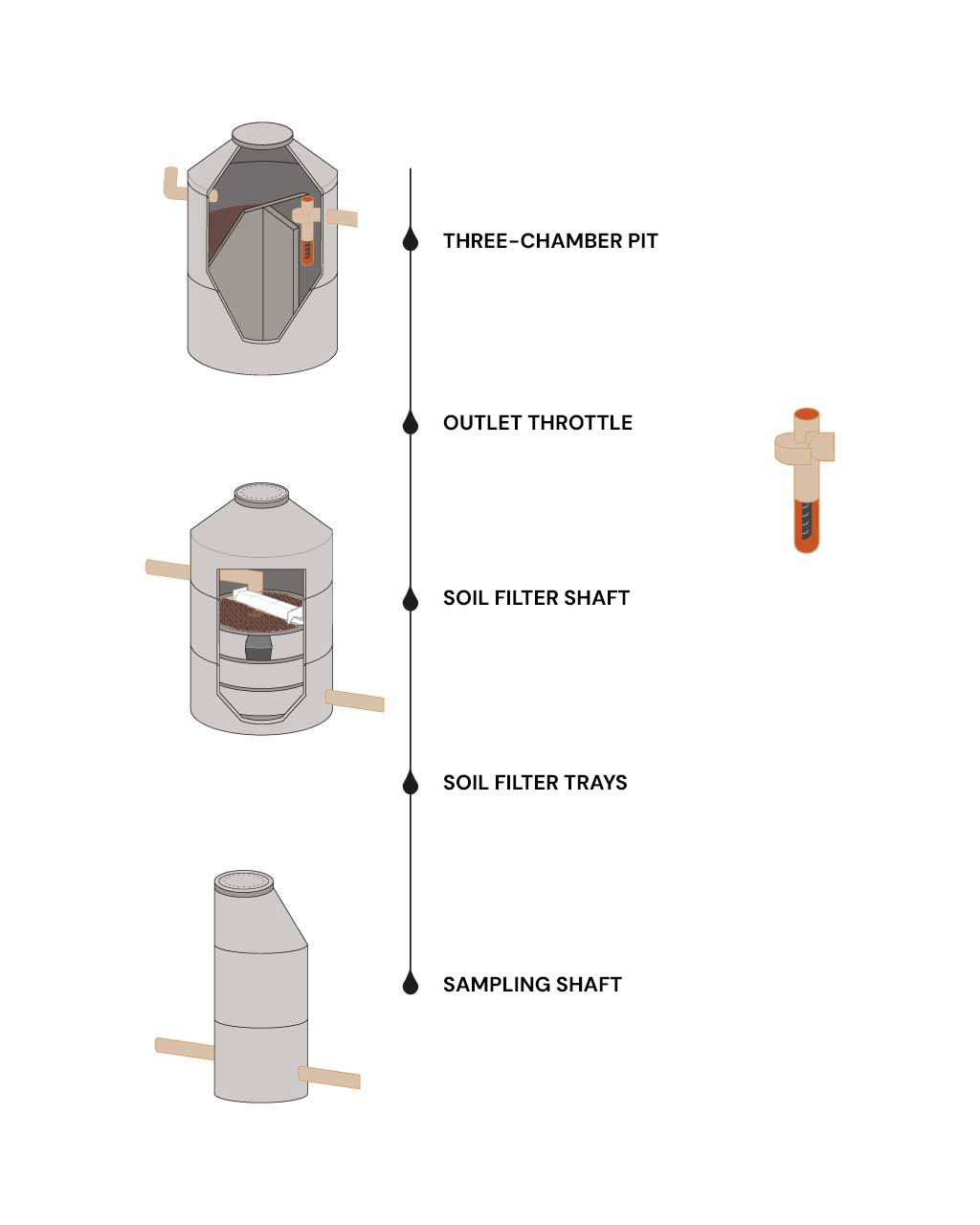

The AQUATO® Soil Filter System treats wastewater through a multi-stage, natural process without any external power supply. The wastewater first flows into a three-chamber pit for mechanical pre-treatment, where suspended solids settle out. A patented outlet throttle ensures uniform outflow and retains additional suspended solids. The pre-treated wastewater then enters the Soil Filter shaft, where a tilting device evenly distributes it across the filter trays. Microorganism cultures settling on the trays degrade the wastewater pollutants. Aeration of the microorganisms occurs passively via a DN150 outlet pipe, which draws oxygen into the tank via a chimney effect, ensuring proper function. The sampling shaft provides easy access to retrieve the treated water.

How does the BKF work?

The AQUATO® Soil Filter System treats wastewater through a multi-stage, natural process without any external power supply. The wastewater first flows into a three-chamber pit for mechanical pre-treatment, where suspended solids settle out. A patented outlet throttle ensures uniform outflow and retains additional suspended solids. The pre-treated wastewater then enters the Soil Filter shaft, where a tilting device evenly distributes it across the filter trays. Microorganism cultures settling on the trays degrade the wastewater pollutants. Aeration of the microorganisms occurs passively via a DN150 outlet pipe, which draws oxygen into the tank via a chimney effect, ensuring proper function. The sampling shaft provides easy access to retrieve the treated water.

Soil Filter System

This small WWTP has been tested by the German Institute for Building Technology (DIBt) and operates fully biologically without external electricity. It is characterized by low maintenance requirements and zero electricity costs. Unlike systems with loose filter media, there is no need to replace filter cascades, and the distribution remains clog-resistant. The large sludge storage volume extends emptying intervals. Based on DIBt approval, the plant is designed for carbon degradation and nitrification. Since its initial building approval in 1989, over 12,000 units have been installed.

Low Maintenance Requirements

Maintenance of the Soil Filter shaft is only required twice annually in accordance with building approval. Maintenance contracts ensure professional, cost-effective servicing, including the determination of effluent values.

Low Operating Costs

Operating costs remain low thanks to the large sludge storage volume, enabling extended disposal intervals. Since no additional sludge is produced in the biological stage, there are no further expenses for power, aeration motors, or compressors.

Proven Technology

The Soil Filter System has proven to be an effective process in numerous studies. As early as 1988, the Technical University of Munich found its purification performance exceeded manufacturer specifications. Effluent values for the "C" and "N" classes are consistently met or even surpassed. The system complies with DIN 4261 Part 2 and EN 12566. In addition to receiving CE marking from a certified body, it was one of the first systems to achieve the BDZ quality label.

High Operational Safety

he Soil Filter System maintains full purification performance even with fluctuating inflows or extended standby periods. This reliability stems from the biological stage's strong buffering capacity and the robust, non-mechanical construction. Thanks to the closed, underground design and targeted ventilation, noise, mosquitoes, and odors are eliminated. Quick installation is ensured by factory pre-assembled components and concrete tanks made of quality-monitored C35/45 (wu) concrete.

Ready to Assist.

Let our expertise guide you. Contact us for a personalized consultation and receive detailed information about our systems and available extensions.

Provide your email – we’ll contact you soon.